An Evaluation of Blank-Out Sign Technology for Use in the City of Charlotte

In 2006 City of Charlotte Department of Transportation (CDOT) conducted an evaluation of the available blank-out signs, and since that time CDOT has been using the same manufacturer of blank-out signs. Knowing that technology advances have occurred during those years, CDOT decided to conduct an updated evaluation of blank-out sign products. The results of the technical evaluation will provide CDOT the basis for selecting a vendor for future blank-out signs purchases.

Study written by the City of Charlotte Department of Transportation

Statement of Purpose

In 2006 City of Charlotte Department of Transportation (CDOT) conducted an evaluation of the available blank-out signs, and since that time CDOT has been using the same manufacturer of blank-out signs. Knowing that technology advances have occurred during those years, CDOT decided to conduct an updated evaluation of blank-out sign products. The results of the technical evaluation will provide CDOT the basis for selecting a vendor for future blank-out signs purchases.

Evaluation Process

CDOT worked with the City’s Procurement office to issue an Invitation to Bid (ITB) for nationwide reach. Contained in the ITB were some required specifications for the sign as well as the requirement to submit a sample sign for testing. The specifications contained only a few particular preferences of CDOT, such as symbol height, general appearance of the sign, and sign size. CDOT left it to the manufacturer to provide specifications on their individual product, such as how the sign is wired.

Equipment to be evaluated

Sample signs from four different manufacturers were received by the date and time specified in the ITB.

- National Sign and Signal

- Orange Traffic

- SESA

- Signal Tech (two signs received)

Evaluation Criteria and Performance Results

The evaluation criteria includes the following:

- Internal and external inspections of the signs

- Continuous illumination and intermittent flashing to test the LED bulbs

- Ease of installation

- Legibility of the sign at 150-ft., 250-ft., and 400-ft. distances in daytime and nighttime conditions

- Conformance to the specifications provided by CDOT

Points were given to each sign based on its performance with 1 being failure and 5 being excellent.

The five signs received were also evaluated based on the following descriptions provided in the ITB:

1.25 Initial Evaluation of Samples: Upon receipt of the sales, a committee of City employees (the “Evaluation Committee”) will conduct an initial evaluation to determine compliance of each sample with the specifications listed in Section 4 of this ITB.

The initial evaluation phase shall consist each sample being tested and evaluated for approximately sixty (60) days. The evaluation criteria shall consist of, but not limited to:

- Performance in field testing;

- Internal and external inspections of the signs;

- Ease of installation, including relative weight of product;

- Appearance of sign when illuminated;

- Light source redundancy.

Internal and External Inspections

CDOT and Procurement staff unpacked the signs from shipment and performed an internal and external inspection of each sign.

National Sign and Signal: This sign has a narrow visor or hood. The sign dimensions are 24” x 30” inside the visor, with the sign face itself being approximately 3/4” smaller in both directions. The exterior is black metal and has two toggle latches to secure the housing. Inside the sign is simple wiring with two ballasts, one for each sign message. The ballasts are mounted on the side of the housing under a protective cover providing a clean look inside the sign, but would make for difficult angles should they need to be replaced as the screws holding the cover are difficult to access . The photocell is large and located on the top right of the sign housing. In spite of following the directions, the photocell failed to dim the sign display. When compared with the specifications for the sign face all spacing and sizes were correct.

SESA: This sign face does not have a cover but rather the individual LED’s are recessed into the sign face. This creates the possibility of each LED grommet being a point for water intrusion. The exterior is black metal and has a special triangular-shaped key that is needed to secure the face to the housing. The interior contains exposed wiring of each LED along with extra LED’s attached to the back of the face. There are three toggle switches inside the sign which change the sign message. This sign had the most complex wiring of the samples submitted. There are three photocells located toward the middle of the sign face and the dimming functions were verified to work properly. Spacing and sizes on the sign face met all specifications except between the “Right” and “Turn” which was under the 2 inch minimum spacing.

Orange Traffic: This sign has a large visor or hood to reduce sun glare on the sign face. The photocell for automatic dimming is located toward the top of the sign face. The inside face dimensions of the sign are 30” x 36” and the sign face met all specifications except the spacing between “Right” and “Turn”. The exterior is black metal and has two toggle latches to secure the housing. Inside the sign uses a hot swappable card system to power the displays which would make for quick and easy repairs.

Signal Tech: These signs do not have a visor or hood. The exterior is black metal and has two toggle latches to secure the housing. Inside the sign is simple wiring with a separate set of redundant power supplies for each of the two displays. Photocells are located in the sign face, and the automatic dimming was very subtle changes spread over a period of time. The manual dimming requires an external box be connected to the board and control be switched over to manual using DIP switches within the sign. Technically this met the spec, as written, but this feature was intended to be a field adjustment that worked along with the automatic dimming. When the faces were compared with the spec the yield symbol was found to be under the required thickness, and the vertical spacing between the words in the “No Turn On Red” display was below the minimum.

Figure 1: CDOT Aerial Crew Pulling New Signal Cable

Field Installation and setup characteristics

The ITB specified the sample signs be equipped with bracket for span wire installation. The signs were hung on the test signal span at CDOT/Transportation Operations facility and wired to the test signal control cabinet.

Figure 2: Using a bucket hanger to hang the blank-out signs and initial issues with National Sign and Signal Sign and SESA sign

National Sign and Signal sign came already equipped with the bracket attached. This sign was easily hung on the span wire and has a small visor or hood to reduce sun glare on the sign face. The terminal block for the power connection was very close to the bottom of the sign which made it slightly difficult to connect. This sign did not work properly when connected to the signal cabinet. Only one message was displayed. After some messages back and forth with the vendor, a technical representative came on-site and determined the ballast had failed, possibly damaged during shipping. By the time the representative was on site, neither message was working. The representative returned a few days later, requested the sign be removed from the span, made repairs, and the sign worked successfully. The sign weighed a total of 65 lbs.

SESA’s sign was equipped with the span wire bracket attached. The sign was easily hung and did not have a visor. However, the sign was not wired to be controlled by the signal cabinet, due to a misinterpretation of the verbiage in the ITB. After some messages back and forth with the supplier, a sales representative came on site and managed to replace a part which enabled the sign to be controlled by the signal cabinet. While on the span wire, opening the door to work on the sign caused it to swing away to a difficult angle. Because of this the vendor representative had to remove the sign from the span to perform the repairs. The SESA signed weighed a total of 60 lbs.

Orange Traffic sign came already equipped with the bracket attached. This sign was easily hung on the span wire and worked properly when connected to the signal cabinet. The Orange Traffic sign was the heaviest of the signs submitted at 80 lbs.

Signal Tech signs came with the span wire brackets shipped separately. One sign had two hangers attached to the top for two brackets to be mounted, because of this the angle the sign would be positioned would depend upon the angle of the span wire. It could not be adjusted to face any direction other than perpendicular to the span. The other sign did not contain any way to attach the bracket. Neither sign had a hole for the signal cable to enter the box of the sign to power it. Due to a misunderstanding of the verbiage in the ITB, the supplier assumed that CDOT would be attaching the bracket and cable. The Signal Tech representative came on site immediately to attach the brackets and drill the hole for the cable for both signs. Both signs then were able to be hung on the span wire, connected to the signal cabinet and worked properly. The representative also explained that just a gooseneck to prevent water and moisture intrusion was insufficient and the sign needed to be completely sealed to operate properly. The single bracket version weighed 60 lbs., and the two bracket version was a total of 65 lbs.

Figure 3: Both messages for National, SESA, Orange Traffic, and Signal Tech signs

Daytime and Nighttime Legibility and Alignment

All five signs were observed at 150-foot, 250-foot, and 400-foot distances in both the daytime and nighttime. Signs were rated on their legibility and the performance if alignment was off center and viewed from an angle greater than approximately 25 degrees.

The signs were very legible from the 150-foot distance in both the day and night testing. At the short distance the SESA yield and pedestrian symbols did not give the appearance of being solid in comparison to the other signs. Upon moving to the 250-foot distance the National Sign and Signal sign began to have glare issues and the symbols display began to look washed out for the daytime testing. During the nighttime 250 and 400 feet testing both the NSS sign and the SESA sign were so bright the letters began to blur together and were no longer legible. The all text display remained legible for the Orange Traffic sign at all distances both night and day, but the symbols display became difficult to read at the 400-foot distance. The text on the Signal Tech signs also performed well out to the 400-foot distance but the tight spacing led to the words beginning to blur together. The Orange Traffic sign consistently outperformed the other signs in the legibility tests scoring the highest ratings in all except the symbols display at 400-feet during the day for which Signal Tech was rated higher.

When viewed from an angle for the alignment test, the Orange Traffic sign showed no issue. The Signal Tech sign didn’t fade but the white LED’s had a yellow hue to them when viewed at an angle. National Sign and Signal experienced fading and SESA’s sign drastically faded when viewed off center.

Figure 4: National, SESA, Orange Traffic and Signal Tech illuminated from 150’

Figure 5: Words message nighttime legibility at 150′; National, SESA, Orange Traffic, Signal Tech (2)

Continuous Illumination and Intermittent Flashing

This criteria is based on the durability of the LED’s and how the sign is wired for continue use at signalized intersections. The signs are connected to a traffic signal control cabinet. The controller in the cabinet is changing between messages for a period of approximately thirty days.

After initial repairs, all signs functioned well for the full 30 day test period. The two Signal Tech signs showed a slight issue during the intermittent flashing testing. When switching from the “Right Turn Yield to Pedestrians” display many of the red LEDs in the yield symbol remained illuminated for a second after the rest of the display turned off and had slightly higher delay in the time the displays turned on compared to the other signs.

Figure 6: Symbols message nighttime legibility at 150′; National, SESA, Orange Traffic, Signal Tech (2)

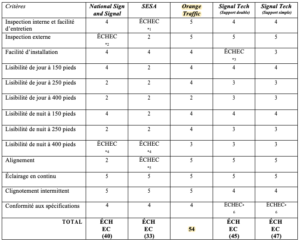

Full Results

*1 SESA sign failed the Internal Inspection and Ease of Maintenance portion of the evaluation due to the complex exposed wiring within the sign

*2 National Sign and Signal sign failed automatic and manual dimming portion of external inspection testing. No dimming features worked during the testing

*3 Signal Tech sign failed ease of installation portion of testing because of the two bracket hanging system making for a much more difficult installation and lack of adjustability if the span is not perpendicular to the approach

*4 Both the National Sign and Signal and SESA sign failed the 400-ft Nighttime Legibility portion of the test because the brightness caused the entire message to blur together and become completely illegible

*5 SESA sign failed the alignment portion of testing due to the drastic fading seen when viewed from an angle

*6 Signal Tech sign was unable to automatically dim once adjusted manually. Specification required both features, not one or the other.

Conclusions

After evaluating the blank out signs in several different categories the Orange Traffic sign clearly outperformed all other submissions. It was given top legibility scores in almost all conditions, angles and distances, and was the only submission that was completely functional upon arrival. The modular card system running the display allows for quick and easy field repairs in comparison to the other designs. All the other signs had issues that the Evaluation Committee deemed as serious enough to warrant removing the signs from consideration. The problems found will be explained in further detail for each sign below:

National Sign and Signal: The most significant issues with this submission were the nighttime legibility and the lack of working dimming capabilities. The most frequent complaint of our current deployed blank-out signs is difficulty for elderly citizens to read the signs at night due to them being overly bright and the message blurring together, so this would be a major issue. At night, beyond the 150-foot distance the messages became very difficult to read and at 400-feet it was illegible. The technicians also found the ballasts and ballast cover difficult to remove and replace with the sign hanging on the span wire. Taking the sign down every time it needs to be repaired is a major fault.

SESA: This sign had multiple issues throughout the testing. The biggest problem observed was the drastic fading of the message when viewed from an angle. The complex internal wiring, special key needed to open, and the angle the sign hangs at when the door is open made it difficult to repair while on the span wire and it would probably have to be taken down in most cases. In the nighttime legibility testing the brightness made the sign difficult to read at the 150-foot and 250-foot distances and complete illegible at the 400-foot distance.

Signal Tech: The requirement of the sign being completely sealed would add a considerable amount of work to the installation process and an additional point of failure. The manual dimming was to adjust the maximum brightness level for the auto dimming feature. Once the sign has been adjusted to the desired brightness level manually it is no longer capable of automatically dimming. The sign also showed greater delay than the other signs when turning on the displays and the red LEDs stayed on for a second or two after the message was turned off. The small vertical spacing of the all text message reduced the legibility of the message at night and the legs of the yield symbol were not wide enough.